- Keterangan

- Siasatan

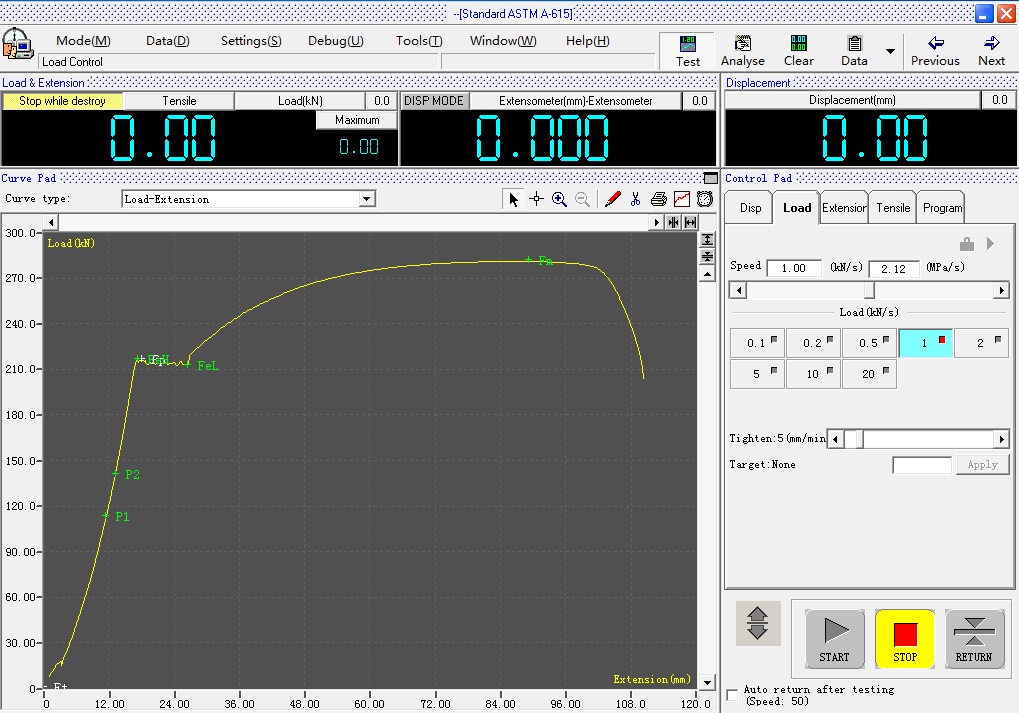

ASTM A615 A615M-16 Cacat dan Bar Karbon-Keluli Biasa untuk Tetulang Konkrit

WAW-2000L Computerized Electro-hydraulic Servo Tensile Testing Machine

(2000Kn, zon ujian tunggal, bidirectional cylinder, side action tensile grip, 0.5 Kelas)

1. Aplikasi:

WAW-2000L Computerized Electro-hydraulic Servo Tensile Testing Machine is a single test space on the lower position of load frame, with oil-cylinder mounted on the top position. Due to large and lower test space, quickly loading speed, it makes it more flexible for tensile testing of large strength metal materials, especially suitable for long length specimen, like deformed steel bar, Dll. It greatly improves the test efficiency, it is very popular in some big steel and iron manufacturing companies for high testing frequency.

It adopts four column structure, kekakuan yang tinggi. Ia menggunakan sel beban ketepatan tinggi untuk mengukur daya ujian, encoder to measure displacement of piston stroke, extensometer elektrik untuk mengukur pelanjutan. Close loop control software can auto get test ultimate tensile strength Rm, yield strength ReH, Max. pasukan ujian Fm, sambungan tidak berkadar Rp0.2, kadar pemanjangan A%, dan lain-lain keputusan ujian. Dalam standard ujian, ia mematuhi piawaian antarabangsa, like ISO15630-1, BS 4449, ASTM A615, ISO6892, ASTM E8, JIS Z2241, Dll.

2. Lembing utamacifications:

2.1 Max. Daya ujian: 2000 Kn;

2.2. Julat pengukuran ketepatan: 1%-100%;

2.3 Menguji ketepatan daya: ±0.5% daripada nilai bacaan

2.4. Julat kawalan kadar tekanan: 1-60IP/S;

2.5. Laraskan julat kadar tekanan ujian: 1N/mm2S-1-60N/mm2S-1;

2.6. Laraskan julat kadar ketegangan ujian:0.00025/S-0.0025/S;

2.7. Ketepatan pengukuran ubah bentuk: ±0.5%;

2.8. Ketepatan pengukuran anjakan: ±1%;

2.9. Julat kawalan kadar anjakan: 0.5mm/min-200mm/min;

2.10. Maximum tensile space: 650Mm;

2.11. Diameter pengapitan bar: φ20-φ50mm;

2.12. Ketebalan pengapit spesimen rata: 0-50Mm;

2.13. Diameter plat atas dan bawah: 300×450mm;

2.14. Strok omboh: 650Mm;

2.15. Pengukuran ubah bentuk: panjang tolok extensometer: 200Mm; Sambungan: 100Mm;

2.16. Bekalan kuasa: 3-fasa 4-wayar, 380V, 50 Hz, 7.5Kw

2.17. Dimensi: Host machine 1280×880×3700(Mm) Pek kuasa: 850×1060×1220(Mm)

2.18. Berat badan: Host machine 7500kg, Pek kuasa: 800Kg.

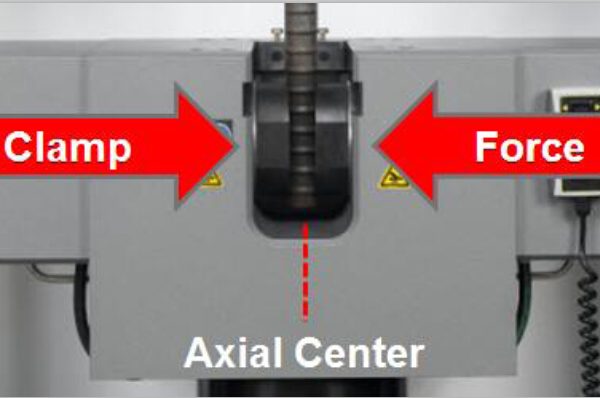

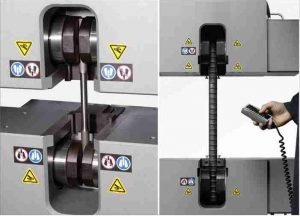

3. Side action hydraulic tensile grip:

- Compared with wedge type hydraulic grip, this side action hydraulic grip has advantage of gripping the sample without any initial gripping force.

- Excellent axial alignment avoids lateral loading.

- Cylinders are inserted inside the grip body; dual direction clamping can ensure good proper alignment regardless of sample thickness varying.

- Piston is made of alloy steel with high hardness and abrasion resistance.

- It equips round tensile jaw and flat tensile jaw for testing rebar with diameter φ8mm-φ50mm

4. English testing software:

Untuk maklumat lebih terperinci, sila hubungi kami E-mel: sales@victorytest.com