- Description

- Inquiry

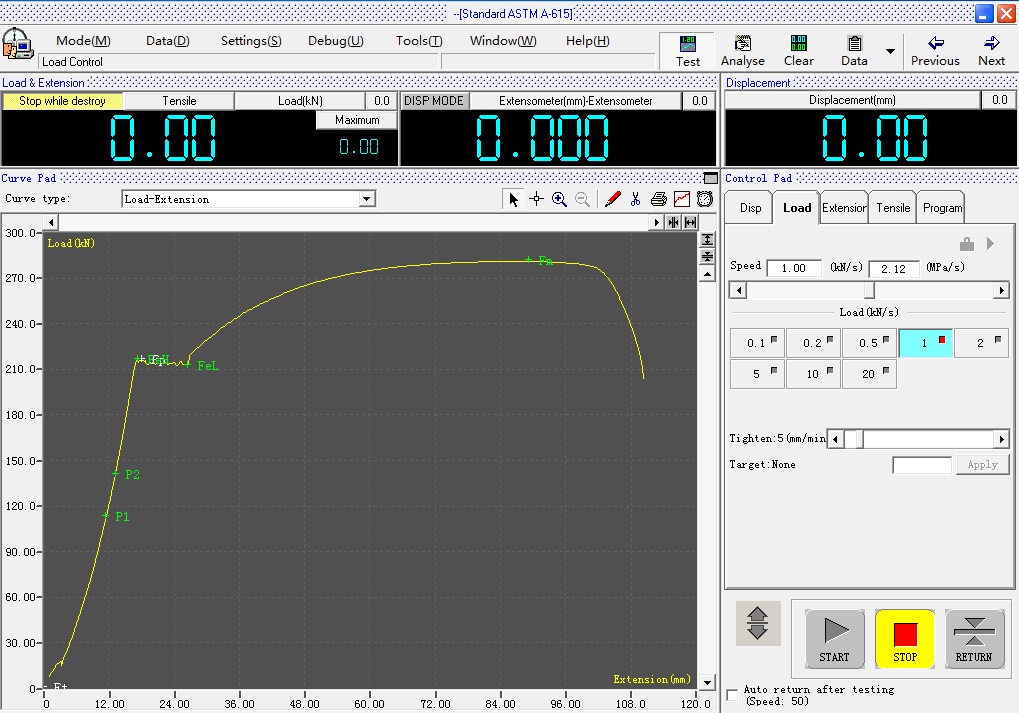

ASTM A615 A615M-16 Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement

WAW-2000L Computerized Electro-hydraulic Servo Tensile Testing Machine

(2000kN, single test zone, bidirectional cylinder, side action tensile grip, 0.5 class)

1. Applications:

WAW-2000L Computerized Electro-hydraulic Servo Tensile Testing Machine is a single test space on the lower position of load frame, with oil-cylinder mounted on the top position. Due to large and lower test space, quickly loading speed, it makes it more flexible for tensile testing of large strength metal materials, especially suitable for long length specimen, like deformed steel bar, etc. It greatly improves the test efficiency, it is very popular in some big steel and iron manufacturing companies for high testing frequency.

It adopts four column structure, high stiffness. It uses high accuracy load cell to measure testing force, encoder to measure displacement of piston stroke, electric extensometer to measure extension. Close loop control software can auto get test ultimate tensile strength Rm, yield strength ReH, max. testing force Fm, non-proportional extension Rp0.2, elongation rate A%, etc testing results. In testing standard, it conforms to international standards, like ISO15630-1, BS 4449, ASTM A615, ISO6892, ASTM E8, JIS Z2241, etc.

2. Main specifications:

2.1 Max. Test force: 2000 kN;

2.2. Measurement range of accuracy: 1%-100%;

2.3 Testing force accuracy: ±0.5% of reading value

2.4. Control range of stress rate: 1-60MPa/S;

2.5. Adjust range of test stress rate: 1N/mm2S-1-60N/mm2S-1;

2.6. Adjust range of test strain rate:0.00025/S-0.0025/S;

2.7. Precision of deformation measurement: ±0.5%;

2.8. Precision of displacement measurement: ±1%;

2.9. Control range of displacement rate: 0.5mm/min-200mm/min;

2.10. Maximum tensile space: 650mm;

2.11. Clamping diameter of rebar: φ20-φ50mm;

2.12. Clamping thickness of flat specimen: 0-50mm;

2.13. Diameter of upper and lower plate: 300×450mm;

2.14. Piston stroke: 650mm;

2.15. Deformation measurement: extensometer gauge length: 200mm; extension: 100mm;

2.16. Power supply: 3-phase 4-wire, 380V, 50 Hz, 7.5kW

2.17. Dimension: Host machine 1280×880×3700(mm) Power pack: 850×1060×1220(mm)

2.18. Weight: Host machine 7500kg, Power pack: 800kg.

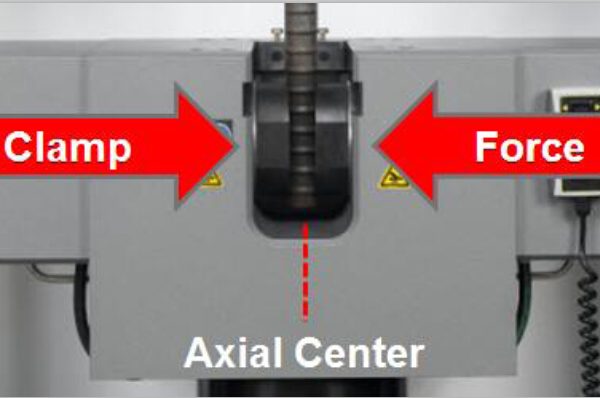

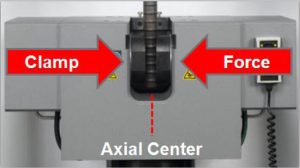

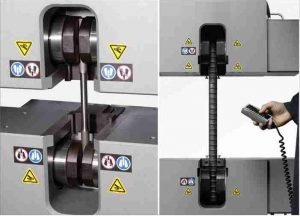

3. Side action hydraulic tensile grip:

- Compared with wedge type hydraulic grip, this side action hydraulic grip has advantage of gripping the sample without any initial gripping force.

- Excellent axial alignment avoids lateral loading.

- Cylinders are inserted inside the grip body; dual direction clamping can ensure good proper alignment regardless of sample thickness varying.

- Piston is made of alloy steel with high hardness and abrasion resistance.

- It equips round tensile jaw and flat tensile jaw for testing rebar with diameter φ8mm-φ50mm

4. English testing software:

For more detailed info, please contact us Email: sales@victorytest.com